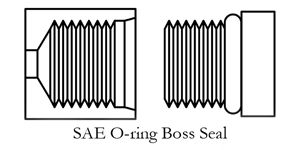

There are several connections that are used for higher pressure connections where taper seals are not ideal. These connections use either a metal to metal seat or an o-ring seal to make a pressure tight seal at high pressures.

SAE Seal

Design: The SAE (Society of Automotive Engineers) o-ring boss seal uses a male fitting with an o-ring to seal in a female port with an angled section where the o-ring seats. Unlike NPT seals that stretch the female portion, SAE seals use straight threads and therefore do not damage the mating part.

Applications: This seal is popular in automotive applications and in other situations where heating, cooling and vibration are an issue. All ports on Ralston Instruments hand pumps, calibration manifolds, volume controllers and fluid traps use an SAE o-ring boss seal.