While there are numerous applications where pressure testing can be done safely and accurately in the field, there are many situations where bench testing, or calibration in the lab, is the preferred method. This involves completely removing the process instruments from where they’re installed (pipeline, boiler, instrument, etc.) and taking them to a lab for calibration. Because they contain small gears and moving parts, analog pressure gauges are particularly susceptible to overpressure, extreme temperature, corrosion, moisture, and vibration that are common to many field applications, so a benchtop calibration is often the most practical option when calibrating analog gauges. Labs are climate controlled and use pressure references with higher accuracy than those typically used in the field. And when tasked with testing multiple gauges that require different levels of pressure, bench testing makes it much easier to compile all the testing equipment together in one place.

How to Bench Test an Analog Gauge

A Step by Step Guide

Bench testing an analog gauge is a relatively simple procedure. Before you get started, make sure you’re using a traceable pressure reference that’s been calibrated to the manufacturer’s specifications with an accuracy that is typically 4 times greater than that of the device being calibrated. You’ll also need a pressure source, and depending on the gauge you’re calibrating, a flathead screwdriver to make adjustments.

1: Connect Your Devices

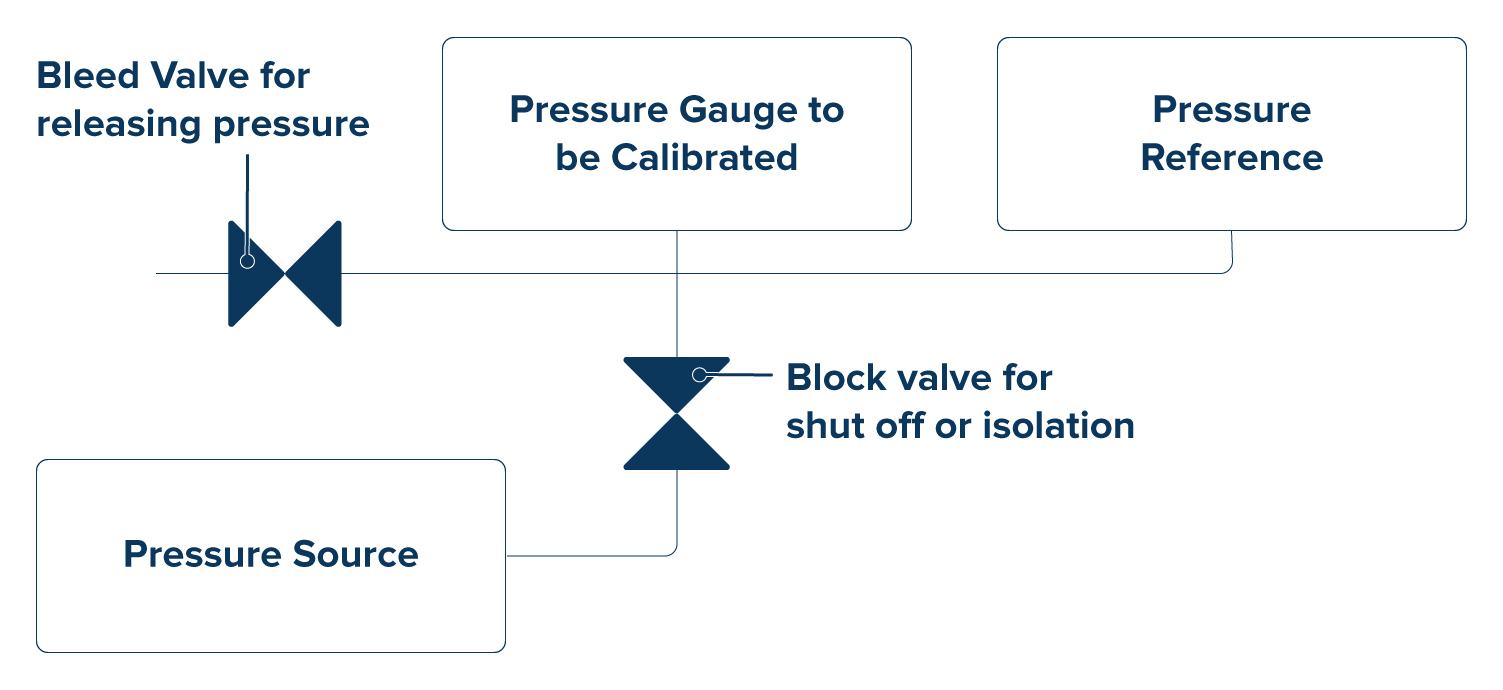

Connect the gauge to be calibrated, the pressure reference, and a pressure source (typically a hand pump or comparator).